Molded rubber parts, produced by injection molding or pressing, usually involve more manipulation than is the case with plastic parts. Rubber tends to stick in the mold cavities and can hardly be processed without burrs. For this reason, and because the elasticity makes the molded rubber parts tangible only with "know how," robots have so far hardly been used to relieve the machine operators, although considerable productivity gains can be expected with them, analogous to thermoplastic injection molding, and the steadily increasing shortage of personnel can be countered. The Motzner injection molding company in Mittenwalde-Motzen, south of Berlin, owned by the König family, which has been in existence for over 90 years, entered into a dialog with the Bavarian injection molding machine manufacturer LWB Steinl for this purpose. The result of this cooperation are the two examples of entry into automation technology presented below.ology.

The beginnings of “Motzener Gummi- und Kunststoffverarbeitungs-GmbH” in Mittenwalde / Motzen, about 20 km south of Berlin, date back to 1931. In that year, the Berlin entrepreneur Hermann Buchholz, one of the early injection molding pioneers, founded a branch plant of his Berlin BEZET-Werk Hermann Buchholz GmbH in Mittenwalde - Motzen. (More details in the company factbox attached below). Now over 90 years old, it has survived a checkered history of war, nationalization and successful re-privatization. Today, with 65 employees and 35 injection molding machines on a production area of 3000 m2, the company produces an extensive range of rubber, plastic and multicomponent parts and, thanks to an in-house design and development department combined with a moldmaking shop, is an efficient development partner (details at www.motzener.de)

High-performance O-rings and profile seals with diameters of up to 1,650 mm, molded rubber parts, as well as 2-component moldings in micro to medium size and technical plastic parts are the expertise and range of products offered by the Brandenburg-based company Motzener Gummi- und Kunststoffverarbeitungs-GmbH.

But what is an increasingly scarce resource in production, despite all the efficiency, is personnel. Operating personnel who are willing and able to put up with the demanding working conditions in rubber parts production. These are, in particular, the 150 to 180 °C hot surfaces of the injection molds from which the moldings are removed or into which usually preheated metal parts are inserted. A further challenge in this specific case is that many rubber parts produced are either very large or very small. The large moldings are special O-rings or profile sealing rings for large machine hydraulics. At the other end of the size scale are also seals, but here in the tenth of a gram range for electrical components and hydraulic valves. Both require manipulation skills and stamina during an 8-hour shift.

But before specific solutions for the personnel bottlenecks in production were on the agenda, there were process engineering concerns that paved the way to the Bavarian machine manufacturer LWB Steinl. The aim was to improve the plasticizing quality of the processed rubber compounds, specifically to reduce the tendency to deposit residues in the mold cavities. This was high on the agenda because the large sealing rings produced must have a brilliant surface in order to fix themselves so firmly in the sealing seats by adhesion that they cannot be twisted or deformed. Material residues on the cavity surfaces are therefore counterproductive and cleaning stops in production are always necessary, which is a significant complication with the large molds with hot surfaces. This problem was to be eliminated or minimized by investing in new machine technology.

The recommendation of a material supplier finally led to LWB Steinl. Extensive material tests were the next step. Here, the LWB-specific EFE plasticizing and injection unit was able to impressively demonstrate its advantages. In particular, the piston injection unit downstream of the FIFO plasticizing unit ensures that all material is completely injected out in every cycle. That ensures, that no cured material is carried over to the next cycle and possibly deposited in the mold cavity. An additional positive effect of the EFE piston injection system proved to be its high injection consistency, which significantly reduced the percentage of insufficiently filled or overfilled molded parts compared to the previously existing machine equipment.

But now to the two automation examples mentioned in the introduction. The first demonstrates how a linear handling on a vertical injection molding machine speeds up part handling despite the hot environment, makes it more consistent and thus helps to increase quality. It was mounted on a vertical, bottom-closing C-frame machine of type LWB-VCEFE 1000/1000 bc (bottom closing) with 1000 cm3 injection volume and 1000 kN clamping force. The linear axis moves laterally and is mounted on the fixed upper C-frame end. The transfer head of the handling unit picks up the O-ring with 4 or more vacuum cups, depending on the diameter and cord thickness, and transfers it laterally to the deposit location on a conveyor that passes through a cooling tunnel. At the end of the cooling section is the takeover position by the operator, who carries out a visual inspection as well as any necessary reworking of the now cooled parts. In addition to the higher productivity, an additional positive effect of the integration of machine and robot into a self-contained production cell is the smaller footprint required compared to a conventional machine/robot configuration, a cost factor that should not be neglected.

LWB sales engineer Thomas Vodnansky and Motzener Managing Director Dipl.-Ing. Matthias König in front of the compact production cell based on the VCEFE 1000/1000 bc vertical machine closing from below.

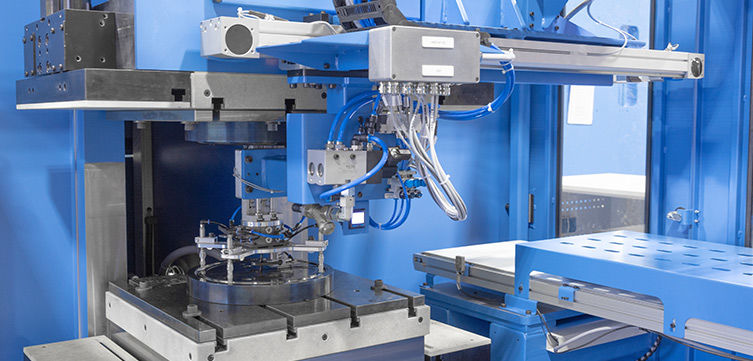

Example two demonstrates handling automation on a machine with a micro-plasticizing unit. It is used to coat a cylindrical metal part with a 0.6 g disc made of FPM. The injection molding machine in the production cell is a vertical VSRS 100 / 6 b with a clamping force of 100 kN and an injection volume of 6 cm3 from the LWB micromachine series. It is combined with a 2-cavity insert molding tool and a 6-axis robot as a "worker" between the injection molding machine and the peripheral equipment. There, on the one hand, the inserts coated with a primer are provided and, on the other hand, the finished parts and the sprue manifold are deposited. The new injection molding machine replaces a conventional vertical machine with an operator attended 8-cavity mold. This became feasible because "downsizing" brought impressive reductions in material start-up losses and part manipulation times. Technology manager Matthias Purann explains: "Compared to the conventional vertical machine with the 8-cavity mold used up to now, the micro injection unit produces only 100 g of startup loss instead of previously 2 to 3 kg of expensive FPM-compound.

At the end of the company tour, Motzener Managing Director Dipl.-Ing. Matthias Koenig summarizes the modernization project handled with LWB Steinl as follows: "Visits to trade shows and discussions with plastics processors had already shown us the efficiency potential of using robots in parts production. We could not yet foresee whether this would also apply to rubber parts production. It was only the discussions with the specialists from LWB Steinl that removed any doubts. And the result is something to be proud of. It's two big steps forward that will certainly be followed by more."

Today's “Motzener Kunststoff- und Gummiverarbeitung GmbH” goes back to the Berlin mechanic Hermann Buchholz (1895 - 1977) and his predecessor company. He is considered the inventor of the first German injection molding machine, with which he produced telephone and microphone bobbins from cellulose acetate. The machine was patented in 1919 (German Reich Patent 441 023), but found no further users in Europe. In the contrary in the USA, where it was patented in 1923, it was built and used by the Grote automobile light manufacturer in Madison-Indiana in a series of 70-80 units for its own use. Also in 1923, Hermann Buchholz founded the company BEZET-Werk Hermann Buchholz GmbH in Berlin-Neukoelln, which still exists today, for the production of electrotechnical insulating materials and plastic articles. In 1931, the plant in Mittenwalde-Motzen was founded as a branch of BEZET-Berlin.

After World War II, the plants were located in different occupation zones (Berlin-Neukoelln in the American zone and Mittenwalde-Motzen in the Russian zone), which influenced their further development. In Motzen, the company was able to continue operating on a private-sector basis until it was nationalized by the GDR-authorities in 1960. By 1978, the injection molding capacity and thus the number of employees had risen to between 100 and 140, producing about 1,000 different molded parts for around 500 customers.

In 1980, the plant was affected by a restructuring of the GDR Council of Ministers, as a result of which the injection molding machines, molds and customer support equipment had to be handed over to other plants. In turn, the company was converted to the processing of elastomers. A new machine equipment had been installed and the production of seals made of rubber and other elastic materials began.

With the fall of communism in 1989 came the change of currency which caused the loss of most Eastern European customers. The company staff had to be reduced to 15 persons, but could be kept alive. As a result, it appeared solid enough to the German privatization agency to agree to a takeover by the management, which took effect on April 1, 1993. Subsequently, under managing partners Thomas König and Bernd Moos, 1.7 million German Marks were invested to reestablish of an injection molding department for processing thermoplastics.

Since 2021, after the sudden death of the second owner, the company his share had been taken over by the König family. Currently, 65 employees with 35 injection molding machines produce high-quality technical injection molded parts and assemblies from thermoplastic materials and elastomers on a production area of 3000 m2. CAD/CAM workstations and an in-house tool shop qualify Motzener as a development partner for precision assemblies. Specialties include the production of large O-rings and profile seals up to 1,650 mm in diameter, as well as rubber-plastic composite parts.

Contact:

Matthias König – Managing Partner

Tel.: +49 (0) 33769 89445

E-Mail: matthias.koenig@kunststoff-gummi.de

Technical Details

Peter Radosai – Sales manager Europa

E-mail: peter.radosai@lwb.de.com

Press Contact

Christina Maniera – Marketing

E-Mail: christina.maniera@lwb.de.com

Author:

Reinhard Bauer – TECHNOKOMM

E-Mail: office@technokomm.at